PREVENTION AND PROTECTION

Electromagnetic fields [0Hz - 300 GHz]

In collaboration with

Generally, it is always possible to find a set of organisational and procedural protection measures for those working activities that involve machines or electrical systems emitting electromagnetic fields, which, if implemented, allow to:

a) prevent the exposure of individuals with absolute or relative contraindications to the exposure levels produced by the equipment;

b) to reduce at a minimum the exposure of workers to electromagnetic fields radiated by such equipment.

Among those measures, the main ones, which are the same for the majority of the exposure conditions, are:

Design and layout

The equipment emitting EMF must be placed in working areas dedicated to the sole use of that equipment and at an appropriate distance from other working areas where the personnel stands for extended periods of time. Moreover, in order to prevent indirect effects, interferential problems and undue exposure, it is of basic importance to avoid that metallic objects of any kind and electrical equipment are placed next to EMF sources, except if an appropriate previous technical assessment has been performed.

In general, the distance between the installation area of the equipment, which we will define as the restricted access area with relation to the risk of EMF exposure, and the other working areas, which are free access areas, depends on the technical features of the equipment and should be estimated by the person who is in charge of risk assessment.

In application of the optimisation principle, it will be appropriate to aim, where possible, at obtaining that the exposure to electromagnetic fields in the areas dedicated to prolonged stay of the non professionally exposed personnel is below the maximum limits established in the current regulations for the general public.

Delimitation of controlled areas

The work areas where the exposure values can be higher than the reference levels for the general public established in the European recommendation 1999/519/EC, which are the same as the reference levels set in the ICNIRP document of 1998, should be delimited by using electromagnetic fields alerting signs, which have to be compliant to the current regulations for warning signs (Figure 1).

|

|

|

| Radiofrequency | Static field | |

|

Figure 1 Electromagnetic fields safety signs |

||

The access to these areas will be allowed only to the authorised personnel, upon verifying the absence of physical contraindications to exposure (See Table 1). The access of non authorised personnel will be prevented by using physical barriers, if possible.

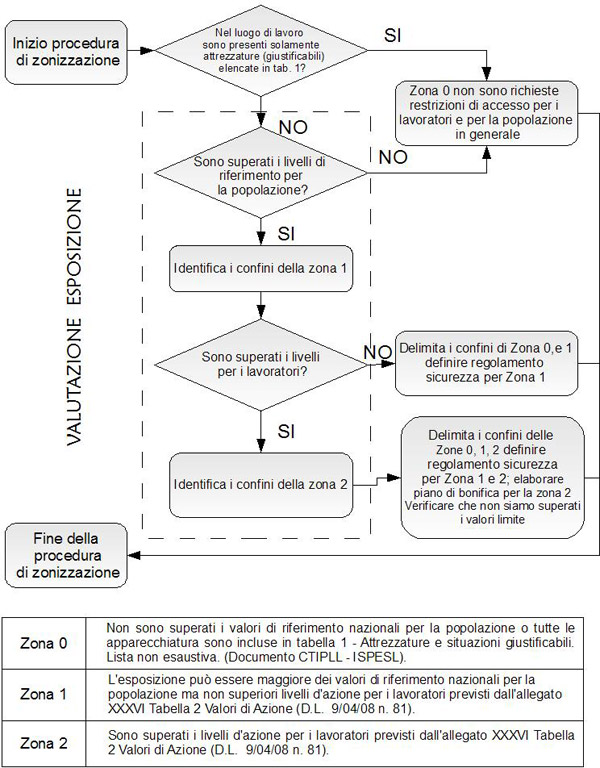

In Figure 2 the flowchart to follow for the purposes of delimiting the restricted access areas, in compliance with the CENELEC EN 50499 standard, is reported.

|

|

Figure 2 Procedure for delimiting the restricted access areas |

Table 1 - Subjects having contraindications to the exposure to electromagnetic fields higher than reference levels established by ICNIRP for the purposes of general population protection (indicative list)

- Carriers of pacemakers or other prosthesis and devices equipped with electronic circuits

- Carriers of vascular clips, devices and endovascular prosthesis, or metallic chips (ferromagnetic chips, in the case of static field, metallic chips, in general, in the case of exposure to RF and microwave)

- Carriers of internal prosthesis

- Pregnant women

- Recent myocardial infarction

- Women carrying intrauterine devices

- Persons who have undergone cataract surgery (only for static magnetic fields)

Worker information and training

For the aim of prevention of risks to health of exposed subjects it is fundamental to train the personnel on the correct behavioural rules to adopt during the operations that take place near the EMF emitting machinery and, above all, on the necessity of limiting the stay in the areas where exposure to electromagnetic fields is of protectionist interest (controlled areas) for the strictly necessary time to the activities and operations related to controlling the EMF emitting machinery/installation.

If the machinery cannot be shielded, the areas that can present values above the action levels for workers should be be adequately indicated and delimited.

If the access to the areas where the risk of overcoming the limit value for worker can't be physically prevented, e.g. in case of work activities on pylons or overhead high voltage electric lines, it is necessary to provide workers with :

- Transportable EMF monitor equipped with an alarm device that promptly give an alert if the action values for the electric and magnetic fields established in the regulations are exceeded.

- Specific protection apparel for the frequencies of interest. In the case of radiofrequency (RF), e.g., this consists in clothing and overalls, protection helmets, gloves and socks. This protection apparel is generally composed by the same synthetic tissues normally employed for fireproof apparel (e.g. Nomex) and by 20-30% inoxidable steel. As an example, in the case of telecommunication equipment (100 MHz - 10 GHz) this kind of apparel provide around 1/10 - 1/100 radiofrequency attenuation.

Moreover, for the purposes of prevention of exposure indirect effects, the personnel must be trained, in particular, on the following elements:

- Cases of contraindication to the exposure to electromagnetic fields emitted by the machinery (Table 1)

- The proper behavioural modalities to adopt near to the machinery, that generally include the prohibition to introduce metallic object of any kind and electrical equipment within the area, if not expressly authorised by the security responsible.

Intervention on the sources: new machinery purchase

According to the Machinery Directive, machinery must be so designed and constructed that any emission of radiation is limited to the extent necessary for its operation and that the effects on exposed persons are non-existent or reduced to non-dangerous proportions. The reference standard for assessment and for reducing the risks generated by radiation emission of machinery is EN 12198-1 of 2009, that deals with the emission of all type of electromagnetic non-ionizing radiation, including optical radiation. Depending on the radiation emission level, the manufacturer shall assign the machinery to a radiation emission category. Those values are reported in appendix B of EN 12198:2009. In particular, the standard considers three emission categories, for which different protection, information and training measures are established, as per Table 2 below.

Table 2: Emission categories of machines according to EN 12198:2009

|

Cat. |

Restrictions and protection measures |

Information - training |

Emission levels |

|

0 |

None |

None |

< reference levels for the general public, European recommendation 1999/519/EC |

|

1 |

Access limitations and protection measures can be necessary |

Informations on dangers, risks and indirect effects |

> reference levels for the general public, European recommendation 1999/519/EC |

|

2 |

Special restrictions and mandatory protection measures |

As 1 more; training is necessary |

> action values according to Directive 35/2013/EC |

The manufacturer shall specify, if necessary, the level of competence that must be achieved by training. Moreover, the manufacturer shall provide adequate instructions in the cases where the operation and installation conditions determine an emission reduction.

If the radiation emission category is 1 or 2, the manufacturer must declare as an additional information the type and the level of radiation that can be emitted by machinery.

Machines belonging to categories 1 and 2 must be marked. Marking must include (Figure 1):

- Safety sign that represents the type of radiation emission

- The category number (category 1 or category 2).

- The reference to the standard EN 12198.