Explanatory note for the standardized procedure suitable for the assessment of the risk arising from WHOLE BODY VIBRATION (WBV)

draft of the standardized procedure

TABLE OF CONTENTS

-

Aim and scope

-

Definitions

-

Procedures for A(8) assessment for individual workers

1. Aim and scope

The aim of this specific standardised procedure for whole body vibration risk, is to enable employers to properly classify workers over the three ranges of exposure provided for by Directive 2002/44/EC:

-

A(8) lower than 0,5 m/s2

-

A(8) from 0,5 m/s2 to 1 m/s2

for the ensuing administrative requirements in terms of:

-

the drafting of the plan for vibration risk reduction being compulsory or not;

-

the implementation of the worker information and training being compulsory or not;

-

the implementation of the health surveillance by the occupational health physician being compulsory or not.

We remind that the Directive 2002/44/EC establishes at Article 5 "Provisions aimed at avoiding or reducing exposure", that workers shall not be exposed above the exposure limit value laid down in Article 3: A(8) = 1 m/s2 . Moreover, Italian laws forbid to exceed an awmax value of 1,5 m/s2 for short term exposures too.

In these cases it is established that the employer shall take "immediate action to reduce exposure below the exposure limit value" .

This is a very important issue, especially when considering there is no anti-vibration PPE, for HAV and WBV, that can safely protect workers and reduce the exposure levels below the limit values, such as, for example, the hearing protectors do when used for the noise-related risk.

In particular, when the limit values are exceeded for short periods (awmax >1,5 m/s2) reducing the risk at source is the only measure that can be adopted to reduce exposure below the limit values set out in the Directive. If in the course of the assessment the limit values are found to be exceeded, it is recommended to refer to the Vibration Database in order to identify any available technological solution offering lower risks, as provided for by the legislation.

If the machinery is not found in the database, the person who is assessing the risk shall perform a market inquiry to find the type of machinery that is suitable to reduce the risk and propose its acquisition when reporting the risk assessment.

In this regard it is important to keep in mind that the data declared by the manufacturer in compliance with the Machinery Directive allow, for each type of machinery, the identification of models providing lower levels of vibration.

The current regulations state that when action values are exceeded (whole body: A(8) = 0.5 m/s2) the employer shall establish and implement a programme of technical and/or organisational measures intended to reduce to a minimum the exposure to mechanical vibration and the attendant risks, taking into account in particular:

-

Other working methods that require less exposure to mechanical vibration;

-

The choice of appropriate work equipment of appropriate ergonomic design and, taking account of the work to be done, producing the least possible vibration.

-

The provision of auxiliary equipment that reduces the risk of injuries caused by vibration, such as seats that effectively reduce whole-body vibration and handles which reduce the vibration transmitted to the hand-arm system.

-

Appropriate maintenance programmes for work equipment, the workplace and workplace systems: in these regards we remind that, an important measure to reduce vibration transmitted to the driving position is the maintenance of the structure of the service areas, the removal of holes and hurdles, the maintenance of the road bed on which handling takes place.

-

The design and layout of workplaces and work stations: a proper and regular maintenance of the used machinery, especially of suspensions and seats, is essential in order to prevent the increase of worker's exposure.

-

Adequate information and training to instruct workers to use work equipment correctly and safely in order to reduce their exposure to mechanical vibration to a minimum: for vibration at the driving position an essential element is the reduction of speed, especially when holes and hurdles are present. Moreover, if the seats are adjustable by weight and height, workers must be trained on the modes of a proper adjustment, that affects in an important manner on the vibration exposure of the workers.

-

Limitation of the duration and intensity of the exposure.

-

Appropriate work schedules with adequate rest periods.

-

The provision of clothing to protect exposed workers from cold and damp.

This standardised procedure can be applied to all productive sectors for the companies with up to 10 employees.

For firms with 11 to 50 employees, the optional application of this procedure is not expected in any case for the firms mentioned in the Italian DLgs 81/2008, i.e.:

-

in the industrial firms subject to the obligation of notification or report in accordance with D.Lgs. 334/1999;

-

in the thermal power stations;

-

in the establishments and installations mentioned in the Italian DLgs 230/1995 and its succeeding modifications;

-

in the firms for the manufacturing and storage of explosives, powers and munitions;

-

in firms in which activities that expose workers to chemical, biological, explosive atmosphere, mutagenic carcinogen risks are performed.

For companies with more than 50 workers, it is not allowed to recur to standardised procedures for risk assessment.

2. Definitions

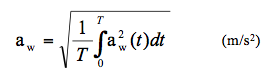

The methods for assessing the risk of exposure to WBV vibration adopted for this investigation are compliant to the international standard EN ISO 2631. These are based on the measurement of the following physical characteristic:

Formula 1

This formula represents the root mean square (r.m.s.) of the frequency-weighted acceleration, expressed in m/s2. This quantity must be measured along each of the three three orthogonal axes of the acceleration vector.

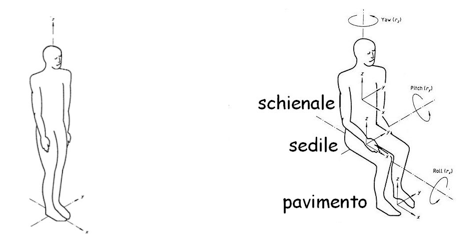

Figure 1 - Definition of the reference axes for the purposes of exposure measurement

Table 1 – Daily action levels and exposure limit values for whole body vibrations (D.L.81/2008)

|

Whole body vibration |

|

|

Daily exposure action value |

Daily exposure limit value |

|

Exposure limit for short periods |

Table 2 – Frequency-weighting curves used for each axis.

| Frequency-weighting | axes |

| Wk | z |

| Wd | x,y |

The assessment of the level of exposure to vibration is based on the calculation of daily exposure A(8) (m/s2) expressed as equivalent continuous acceleration over an eight-hour period, calculated as the highest (rms) value, or the highest vibration dose value (VDV) of the frequency-weighted accelerations, determined on three orthogonal axes.

1.4x awx, 1.4x awy, awz

In accordance to the following formula:

A(8) = a(wmax) x (Te / 8) 1/2

Te: total daily duration of exposure to vibration (hours)

a(wmax) highest value among 1.4X awx, 1.4x awy, awz (for a seated person)

awx, awy, awz : r.m.s. values of the frequency-weighted acceleration (m/s2) along the x, y, z axes (ISO 2631-1. 1997)

3. Procedures for A(8) assessment for individual workers

Assessment and identification of A8 for an individual worker is performed based on a sequence that involves:

-

An investigation of the main vibration sources and different operation modes related to machinery normally used during working activities that expose to WBV.

-

An investigation of the daily duration of each work activity that expose to vibration in the recurring working day at maximum risk. For this purpose, the real daily duration of the time spent by the operator by sitting on the vehicle, that can differ from the normal work schedule: e.g. a driver can end his driving shift, but keep on sitting on the vehicle: in this case, the total duration of the exposure when sitting on the vehicle must be considered.

-

The application of an algorithm for calculating A8, as prescribed by the current regulations and reported above.

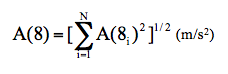

If the worker is exposed to different vibration values, as in the case of the employment of several machineries in a working day, or of the same machinery in different operating conditions that entail different exposures to vibration, e.g. the use of an excavator in the two different excavation and handling phases, the daily vibration exposure A(8) expressed as m/s2, will be calculated as follows:

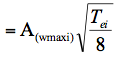

Formula 2

where:

| A8i: | partial A(8) for the i-th operation |

| A8i |

|

| Tei: | exposure duration for the i-th operation (hours) |

| a(wmaxi): | a(wmax) related to the i-th operation |

It is important to consider all the machinery and the different working practices that can significantly contribute to the daily WBV exposure. In brief, in order to have an effective estimation of the daily vibration exposure it is necessary to identify:

-

the sources of exposure to vibration (the machinery and the tools used);

-

the different operations performed with each machinery and the different driving conditions that can affect the vibration exposure, e.g.:

-

an excavator in the excavation, transportation and material handling phases;

-

the transportation activities performed with different road beds and speeds;

-

-

the respective daily duration of each operation must then be associated, as requested by the calculation procedure, to the recurring situation of maximum risk.