Explanatory note for the standardized procedure suitable for the assessment of the risk arising from

HAND-ARM VIBRATION

TABLE OF CONTENTS

-

Aim and scope

-

Definitions

-

Assessment modes of A(8) for the single worker

1. Aim and scope

The aim of this standardized procedure for hand-arm vibration risk, is to enable employers to properly classify workers in the 3 ranges of exposure provided for by Directive 2002/44/EC:

- A8 lower than 2,5 m/s2

- A8 from 2,5 m/s2 to 5 m/s2

for the ensuing administrative requirements in terms of:

- the drafting of the plan for vibration risk reduction being compulsory or not

- the implementation of the worker information and training being compulsory or not

- the implementation of the health surveillance by the occupational health physician being compulsory or not.

We remind that the Directive 2002/44/EC establishes at Article 5, "Provisions aimed at avoiding or reducing exposure", that workers shall not be exposed above the exposure limit values laid down in Article 3: A(8) = 5 m/s2 . Moreover, Italian laws forbid to exceed an awrms of 20 m/s2

In these cases it is established that the employer shall take "immediate action to reduce exposure below the exposure limit value".

This is a very important issue, especially when considering there is no anti-vibration PPE, for HAV and WBV, that can safely protect workers and reduce the exposure levels below the limit values, such as, for example, the hearing protectors do when used for the noise-related risk.

In particular, when the limit values are exceeded for short periods - awrms >20 m/s2- reducing the risk at source is the only measure that can be adopted to reduce the exposure below the limit values set out in the legislation. If in the course of the assessment the limit values are found to be exceeded, it is recommended to refer to the Vibration Database in order to identify any available technological solution offering lower risks, as provided for by the legislation.

If the machinery is not found in the database, the person who is assessing the risk must perform a market inquiry to find the type of machinery that is suitable to reduce the risk and propose its acquisition when reporting the risk assessment.

In this regard it is important to keep in mind that the data declared by the manufacturer in compliance with the Machinery Directive allow, for each type of machinery, the identification of models providing lower levels of vibration.

The current regulations state that when action values are exceeded (hand-arm: A(8) = 2.5 m/s2) the employer shall establish and implement a programme of technical and/or organisational measures intended to reduce to a minimum the exposure to mechanical vibration and the attendant risks, taking into account in particular:

-

Other working methods that require less exposure to mechanical vibration;

-

The choice of appropriate work equipment of appropriate ergonomic design and, taking account of the work to be done, producing the least possible vibration;

-

The provision of auxiliary equipment that reduces the risk of injuries caused by vibration, such as seats that effectively reduce whole-body vibration and handles which reduce the vibration transmitted to the hand-arm system;

-

Appropriate maintenance programmes for work equipment, the workplace and workplace systems;

-

The design and layout of workplaces and work stations;

-

Adequate information and training to instruct workers to use work equipment correctly and safely in order to reduce their exposure to mechanical vibration to a minimum;

-

Limitation of the duration and intensity of the exposure;

-

Appropriate work schedules with adequate rest periods;

-

The provision of clothing to protect exposed workers from cold and damp.

This standardised procedure can be applied to all productive sectors for the firms with up to 10 employees.

For firms with 11 to 50 employees, the optional application of this procedure is not expected in any case for the firms mentioned in the Italian DLgs 81/2008, i.e.:

-

in the industrial firms subject to the obligation of notification or report;

-

in the thermoelectric centrals;

-

in the establishments and installations di cui agli articoli 7, 28 e 33 del Decreto Legislativo 17 marzo 1995, n. 230, e successive modificazioni;

-

in the firms for the manufacturing and storage of explosives, powers and munitions;

-

in firms in which are performed activities that expose workers to chemical, biological, explosive atmosphere, mutagenic carcinogen risks.

For firms with more than 50 employees the use of standardized procedures for risk assessment is not allowed.

2. Definitions

ahw frequency-weighted root-mean-square (r.m.s.) average acceleration, expressed in m/s2 .

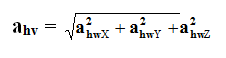

Formula 1

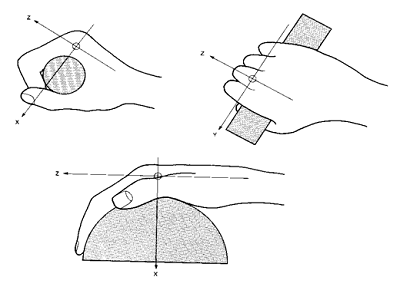

This quantity must be measured along each of the three three orthogonal axes of the acceleration vector. For this purpose the standard EN ISO 5349 defines the orthogonal axes system reported in Figure 1.

Figure 1 - definition of the measurement axes (ISO 5349)

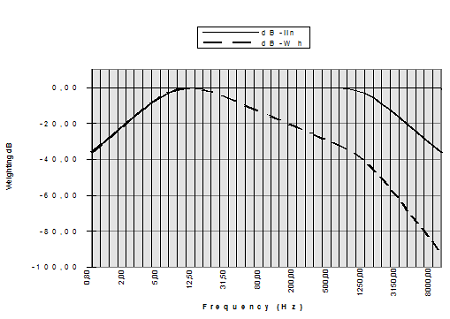

The frequency-weighting curve Wh defined by the standard is the same for each of the three measurement axes and is reported in Figure 2 along with the "linear" weighting filter Wlin, defined by the same standard. From these graphics it appears that, in accordance with this standard, the range of frequencies of occupational interest spans from 8 Hz to 1000 Hz.

Vibration total value, ahv

Formula 2

It is given by the root-sum-of-squares of the component values from the three axes. It is the value to be used when calculating the daily exposure, A(8).

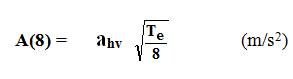

A(8) (m/s2) Frequency-weighted acceleration referred to a 8-hour work.

It is calculated by using the following formula:

Formula 3

where:

Te : Total daily duration of exposure to the vibration (hours)

A(w)sum : (a2 wx + a2 wy + a2 wz)1/2

awi : R.m.s of the frequency-weighted acceleration along the axis i = x, y, z.

3. Assessment modes of A(8) for the single worker

The assessment and identification of A8 for the single worker takes place on the basis of a sequence that involves:

-

An inquiry on the main vibration sources and on the different operation modes applied when using the vibrating tools normally used during working activities

-

An inquiry on the daily duration of each work activity that expose to vibration in the recurring working day at maximum risk. For this purpose, the real daily duration of the contact between the operator hand and the vibrating machinery, that is generally less than the working time with the vibrating machinery, needs to be assessed: e.g. the time required to prepare the material to be processed, to set up the machinery, to move the pieces to be processed shall not be considered in the calculation of the vibration exposure time, when they do not entail the contact of the harm with the vibration source.

-

The application of an algorithm for A(8) calculation

If the worker is exposed to different vibration values, as in the case of the employment of several vibrating tools in a working day, or of the same tool in different operating conditions that entail different exposures to vibration, the daily vibration exposure A(8) expressed as m/s2, will be calculated as follows:

Formula 4

where:

A2(w)sum,i : vectorial sum of the frequency-weighted acceleration for the i-th operation

Ti : Exposure duration for the i-th operation (hours)

It is important to examine all the machinery or the products to be processed and held by the worker that can provide a significant contribution to the daily vibration exposure transmitted to the hand-arm system. In order to have a valid estimation of the daily vibration exposure it is necessary to identify:

-

the sources of exposure to vibration (the machinery and the tools used);

-

the inserted tools and the different operations done with each machinery that could have an effect on the vibration exposure, e.g.:

-

a grinder with an inserted tool such as cutting tool, milling tool or felt

-

a hammer drill with an inserted tool for demolishing or drilling

-

a brush cutter with an inserted tool for cutting with blade or line