Proposal of a noise exposure calculation method for assessment of noise risk in application of Article 6, point 8, letter f, of Legislative Decree 81/2008

Draft standardized procedure

CONTENTS

1. Scope and Field of Application

2. Definitions

3. Procedures for LEX assessment of individual workers

3a – Assessment of the possibility of justification

3b - Identification of the recurring week at maximum risk (settimana ricorrente a massimo rischio, SRMR)

3c - Identification of the LAeq and the relative SRMR exposure times

3d – Correction of the noise source levels considered in the SRMR

3e –Calculation of the exposure level (LEX) in the SRMR

Appendices

Appendix 1 - List of processes with high peak levels

Appendix 2 - List of activities and duties with LEX normally less than 80 dB(A)

Appendix 3 - Calculation of the level of exposure in the recurring week at maximum risk

1. Aim and scope

Whereas noise exposure calculations do not exhaust all noise risk assessment objectives, the aim of this proposal of a specific standardised noise risk assessment procedure is that of enabling employers to properly classify workers over the three ranges of exposure provided for by Chapter II, of Title VIII of Legislative Decree 81/2008:

-

up to 80 dB(A) of LEX

-

from 80 to 85 dB(A) of LEX

-

beyond 85 dB(A) of LEX

for the ensuing administrative requirements in terms of:

-

Whether or not there is a need to redraft the measurement plan pursuant to Article 192, point 2 and to implement the identification, delimitation and limitation of access to noisy areas pursuant to Article 192, point 3;

-

Whether or not there is a need to provide and require the use of personal hearing protectors (PHP) pursuant to Article 193;

-

Whether or not there is a need to provide information and training to workers pursuant to Article 195;

-

Whether or not there is a need for the occupational physician to perform health surveillance pursuant to Article 196.

This proposal of a standardised procedure is to be applied to companies regardless of current risk levels (thereby specifically making unnecessary those acoustic measurements provided for that surpass the lowest action levels, pursuant to Article 190, point 2), notwithstanding that measurement continues to be standard procedure.

This proposal of a standardised procedure is not to be applied to assessment of peak levels. Classification of workers into risk groups based on peak exposure levels may be properly performed through measurement. In Appendix 1 there is a non-comprehensive list of processes with high peak levels of exposure.

This proposal of a standardised procedure may be applied to all manufacturing sectors for companies with up to 10 workers.

For companies with between 11 and 50 workers, optional application of this procedure proposal is not in any event anticipated for companies referred to in point 7 of Article 29, of Legislative Decree 81/2008, in other words:

-

In those industrial companies referred to in Article 2 of Legislative Decree 334 of 17 August 1999, as amended, subject to the requirement to notify or report, pursuant to Articles 6 and 8 of the same Decree;

-

In thermal power plants;

-

In plants and installations referred to in Articles 7, 28 and 33 of Legislative Decree 230 of 17 March 1995, as amended;

-

In companies that manufacture and separately store explosives, powders and munitions;

-

Or in companies where there are activities that expose the workers to risks from chemicals, biological materials, explosive atmospheres, carcinogenic mutagens or connected to exposure to asbestos.

For companies with more than 50 workers, recourse to standardised procedure for risk assessment is not permitted.

2. Definitions

LEX = Personal noise exposure level as defined by Article 188 of Legislative Decree 81/2008. For the purposes of this proposal of a standardised procedure only the LEX,W (weekly) will be referred to.

Recurring week at maximum risk (SRMR) = week that identifies those exposure conditions from which workers are to be protected for at least 95% of those exposure conditions. In terms of application these are those exposure conditions, which may be identified in the third worst week from the standpoint of exposure to noise that occurred in the previous year and which may be reasonably expected in the coming years.

LAeq,i = Weighted equivalent level A referred to the exposure of a worker operating with work equipment or performing a task for a specific time Ti

AHG (Acoustically Homogeneous Group) = This is a group of workers who do the same work and who are likely to undergo similar exposition to noise during the workday. An AHG should be clearly identified with the indication of the names of the workers in the group.

3. Procedures for LEX assessment for individual workers

Assessment and identification of the LEX for an individual worker is performed based on a sequence that anticipates:

-

Evaluation of the possibility to justify the failed analysis of the noise risk assessment (Article 181, point 3) for the individual worker or for the Acoustically Homogeneous Group[1].

-

In the event that it is impossible to justify, the identification of the recurring week at maximum risk for an individual worker or for an Acoustically Homogeneous Group.

-

Identification of the exposure conditions through:

-

Determination of the exposure times referred to the recurring week at maximum risk

-

Determination of the levels found on the Physical Agents Portal – Noise database validated by the Advisory Board pursuant to Article 6 of Legislative Decree 81/2008[2].

-

-

An investigation into work conditions and noise sources considered in the recurring week at maximum risk in order to identify suitable measures for the correction of previously estimated levels.

-

Application of an algorithm for the calculation of the LEX in order to assign the individual worker or the Acoustically Homogeneous Group (AHG) to a specific risk group.

3a – Evaluation of the possibility to “justify”

Verify if the type of manufacturing/services of one's company enables the certain exclusion of the possibility of there being workers exposed to LEX greater than 80 dB(A), Lpeak greater than 135 dB(C) and surrounding conditions that may cause increased auditory risk, in comparison with the indications found in Appendix 2.

1 - Does the type of manufacturing/services of one's company enable it to be placed among those companies that certainly do not exceed 80 dB(A) and have no significant noise risk?

If the answer is Yes, “justify” it (then the determination of LEX for the employees is not necessary)

3b - Identification of the recurring week at maximum risk (SRMR)

If justification is not possible pursuant to the previous point it is necessary to identify the third worst week from the standpoint of exposure to noise that occurred in the previous year and which may be reasonably expected in the coming years [3],

3c - Identification of the LAeq noise levels and their relative exposure times for the recurring week at maximum risk

5- In the SRMR, in decreasing order of noise level, what are the 5 exposure conditions (sources/processes) that cause the greatest exposure to noise? For the 5 conditions identified, define their respective exposure times and enter the data into the table below:

LAeq,1* = ____,_ (dB(A)) and T1 = ___ (min)

LAeq,2* = ____,_ (dB(A)) and T2 = ___ (min)

LAeq,3* = ____,_ (dB(A)) and T3 = ___ (min)

LAeq,4* = ____,_ (dB(A)) and T4 = ___ (min)

LAeq,5* = ____,_ (dB(A)) and T5 = ___ (min)

* : The LAeq values may be drawn from the data found in the Physical Agents Portal – Noise database validated by the Advisory Board pursuant to Article 6 [4]. Workers exposed to noise from a nearby source should have that noise attributed to that source for the calculation. In all cases in which it is not possible to clearly identify the exposure circumstances (e.g. mobile operator in workplaces with many sources – forklift truck drivers or plant inspectors at mills, feed plants or ceramics manufacturers) or in the event that the value assigned by the database is not deemed appropriate, then measurements shall be required.

3d – Correction of noise levels LAeq considered over the recurring week at maximum risk

For each level not greater than 5 LAeq as until now defined, it is necessary to make the following corrections:

LAeq CORRECTED = LAeq + C +D + E +F

|

Correction for soundproof barriers* |

C (dBA) |

|

Very effective soundproofing (e.g. acoustic separation, mufflers, cowling, operator enclosures) that affect all of the noise coming from sources that significantly influence LAeq |

-8 |

|

Effective soundproofing (e.g. pipe insulation, partial cowling, shields) that affect all of the noise coming from sources that significantly influence LAeq |

-4 |

|

Other soundproofing (e.g. anti-vibration systems, environmental treatments) or soundproofing that affect only some of the of the noise coming from sources that significantly influence LAeq |

-2 |

|

No soundproofing |

0 |

* : considering any soundproofing added after purchase of work equipment or environmental treatments; not PHP, based on the 10 categories indicated by the UNI/TR 11347:2010.

|

Correction for Reverberation |

D (dBA) |

|

No reverberation (open environment) |

-1 |

|

Closed area with little reverberation |

1 |

|

Tunnels or very closed spaces (ships holds, cisterns). Locales with high reverberation |

3 |

|

Correction for Crowds |

E (dBA) |

|

Contemporaneous presence of several workers/sources of noise in the immediate vicinity |

2 |

|

Either individual workers or noise sources or those quite distant from one another |

0 |

|

Correction for Maintenance |

F (dBA) |

|

New machines or equipment |

-1 |

|

Well maintained machines or equipment |

0 |

|

Machines or equipment with no maintenance |

1 |

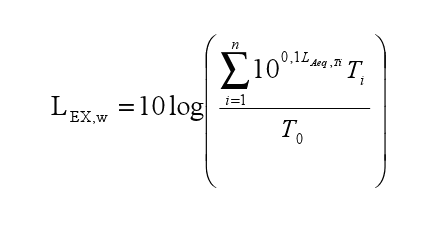

3e –Calculation of the exposure level (LEX) over the recurring week at maximum risk

Refer to the formula in Appendix 3 and to the software provided with this procedure proposal.

Results from the application of the standardised procedure proposal using the procedures described above include uncertainty calculations. Therefore, results of this calculation enable immediate placement of workers or AHGs in one of the 3 risk groups indicated in point 1.

Appendix 1

LIST OF PROCESSES WITH HIGH PEAK LEVELS

|

Use of explosives (explosives technicians in open pit quarries or mine shafts, or for military applications) |

|

Guns or firearms (ecology officers, firing range personnel, police or military personnel, etc.) |

|

Nail guns (for wood, metal, stone, cement, etc.) |

|

Hammering on metal components (plate, steel, aluminium…) |

|

Punching, hammering (metal workers…) |

|

Vibration, punch, etc., presses (foundries …) |

Appendix 2

LIST OF ACTIVITIES AND DUTIES WITH LEX NORMALLY LESS THAN 80 dB(A) [5]

Pertaining to one of the activities or tasks performed within the scope of a specific company or one of the categories listed in the left hand column of the Table below, is not in and of itself an absolute guaranty that noise levels will not surpass 80 dB(A) of LEX; obviously, this is also true, symmetrically for the activities or tasks in the right hand column.

To reduce the probability of possible errors in application of the protocol outlined below it is suggested that companies:

-

Check their own placement keeping in mind the activities or tasks performed by personnel most exposed during the noisiest week of the previous year.

-

Define how long the noisiest work equipment in your company is used considering that just a few minutes using noisy machines or apparatus are needed to surpass 80 dB(A) of LEX.

|

To reach LEX > 80 dB(A) the following are sufficient: |

Standard noise levels for: |

|

30 minutes at 92 dB(A) |

welders, use of hammer and chisels for construction work tractors without cabs ... |

|

15 minutes at 95 dB(A) |

power wrenches, head grinders, circular saws for cutting aluminium... |

|

8 minutes at 98 dB(A) |

disk angle grinders, demolition hammers, ceramics cutters... |

The employer, based on the peculiarities of his/her company, who does not feel that the placement accorded is appropriate, may always verify his/her convictions by entrusting a qualified person with the task of instrumentally testing just one or several extreme situations, reserving the right to commission a complete assessment at a later date with measurements as provided for by Legislative Decree 81/08.

Activity and Task Classification Table

for the purposes of required instrumental measurements

|

Activities that generally do not surpass 80 dB(A) and that generally do not require instrumental measurements |

Activities that cannot be given a definitive placement based on currently available information |

Activities that generally surpass 80 dB(A) and that generally require instrumental measurements |

|

CLOTHING |

||

|

|

|

AGRICULTURE AND AGRO FOOD |

||

|

|

|

|

CRAFT AND ARTISTIC ACTIVITIES |

||

|

|

|

|

VEHICLES |

||

|

|

|

|

CERAMICS AND GLASS |

||

|

|

|

|

CHEMISTRY |

||

|

|

|

|

COMMERCE AND PUBLIC BUSINESSES |

||

|

|

|

|

CONSTRUCTION |

||

|

|

|

|

GRAPHIC ARTISTS AND PHOTOGRAPHERS |

||

|

|

|

|

WOODWORKING |

||

|

|

|

|

METALWORK |

||

|

|

|

|

SERVICES |

||

|

|

|

To close, it should be again recalled that the list above is merely indicative. This is notwithstanding the employer's responsibility to establish if, in specific cases, the LEX exposure levels (depending on both noise levels and exposure time) may reasonably deemed to be less than 80 dB(A).

Note: an empirical method to check if the noise level in a workstation is greater than 80 dB(A) is that of speaking in a normal tone of voice to another person, who has no hearing deficit and does not suffer from any diseases of the ear, and who is performing their normal job duties. The distance between the two persons should be about 1 metre (more or less arms length), avoiding that one or the other is between their interlocutor and the noise source;

If the listener does not understand the words it may be assumed that the equivalent noise level (LAeq) at the workstation/equipment being operated is above 80 dB(A).

Appendix 3

CALCULATION OF RECURRING WEEK AT MAXIMUM RISK

The general formula is applied using the relevant equivalent noise level data and exposure times in the recurring week at maximum risk (SRMR) as referred to in points from 3b to 3e.

With:

LEX,w = level of weekly exposure to noise [dB(A)]

T0 = reference time for LEX,w [2400 minutes or 40 hours]

LAeq,Ti = equivalent level of exposure over the nth amount of time [dB(A)]

Ti = duration of exposure to Leq nth [minutes or hours]

For example assume exposure to the following 5 different exposure conditions during the recurring week at maximum week, with noise levels and times as found in the table below:

|

Equipment: |

Equivalent level Leq,i |

Exposure time Ti |

|

1 |

95 dB(A) |

30 min |

|

2 |

90 dB(A) |

30 min |

|

3 |

89 dB(A) |

180 min |

|

4 |

87 dB(A) |

90 min |

|

5 |

85 dB(A) |

1000 min |

The final result comes to:

LEX,w = 84.2 dB(A)

Therefore, the risk group is intermediate, between the lower and upper action value

[1]It is possible reduce measurements by identifying the AHG, which must be clearly identified along with its composition.

The Acoustically Homogeneous Groups may be identifiable, for example, based job assignment, function, work area and profession. Alternatively, the AHGs may be identifiable through analysis of the work using production, process or work activity criteria.

The AHGs thus identified should be checked by consulting the workers and their supervisor.

[2]This Procedure proposal will also be extended to the determination of the LEX starting with the manufacturer's certification data as soon as the specific analyses have been consolidated.

[3]This is notwithstanding the principle that the assessment should be performed again each time the exposure conditions change significantly, or when the results of the health surveillance show a degeneration of the hearing of the personnel and in any event every four years.

[4]The values that may be drawn from the databases should be used within the limits and those measures indicated by the Authors. Specifically the datum used should arise from exposure conditions that may be superimposed over the one to be described.

[5] List drawn and updated from the guidelines from the CNA - LAPAM-Federimpresa - Confcommercio - Confesercenti - CLAAI and from the Modena NHS Hospital